|

Home : Quarterly Archives : Volume 9 |

Tredyffrin Easttown Historical Society |

|

Source: April 1957 Volume 9 Number 3, Pages 59–63 Clockmakers of Tredyffrin and Easttown townships A method of marking time is one of the first steps toward civilization since the savage had no need for accurate time, and as man became civilized he needed to have some means of calculating his time. At first the sundial was sufficient to answer the need but it was not satisfactory in all areas. It is said that the clock came from the Orient at the time of the Crusades. In colonial America very few people could afford to own a clock, so they had a town clock which, like the town pump, was supported by the people of the community. The "Grandfather" clock, otherwise known as the tall, hall, or long clock, originated about 1680 when the long pendulum was introduced to the chamber or household clocks as an improvement over the short or "bob" pendulum. The case, with which we are familiar today as the distinctive mark of a grandfather clock, originated as a form of protection for the swinging pendulum. This paper is concerned with two grandfather clocks which have been made in Easttown and Tredyffrin Townships. As you step into the entrance hall of the home of Mr. and Mrs. Daniel M. LeFevre on Cassatt Avenue, Berwyn, the first thing which you see is an imposing, grandfather clock. Back in 1908, Daniel LeFevre, a young men married just one year, decided to satisfy his heart's desire to own a grandfather clock. He purchased the wood - solid African mahogany - in Philadelphia at a cost of about $25.00. The lumber which averaged 3/4 inch in thickness was surfaced - that is - it had been put through a planer. Mr. LeFevre then started work in his attic room in the little house next to Chattin's on Waterloo Road in Berwyn. Using kerosene light, he worked on his clock for 360 hours (4 hours every day including Saturdays and Sundays), during that winter. He has reckoned that at a cost cf $.50 an hour (wages at that time) the labor was worth $180.00. The basic design of the clock is Chippendale, with some modifications such as are found many times when a craftsman starts out to create a piece of furniture for himself. The clock measures 7' 11" high, 14" deep, 22" wide; the base is 23" high. There are glass panels on the front and two sides of the clock waist and in the sides of the hood. The important thing to keep in mind is that in building his clock Mr. LeFevre did all the work by hand. The delicate carving of the Corinthian capitals, the grooved columns which support the capitals, all of the moldings, as well as the Wall-of-Troy molding at the top of the waist, the dog-eared panel in the clock base, the Chippendale feet and the urn in the center at the top of the hood of the clock - all were carved by hand.

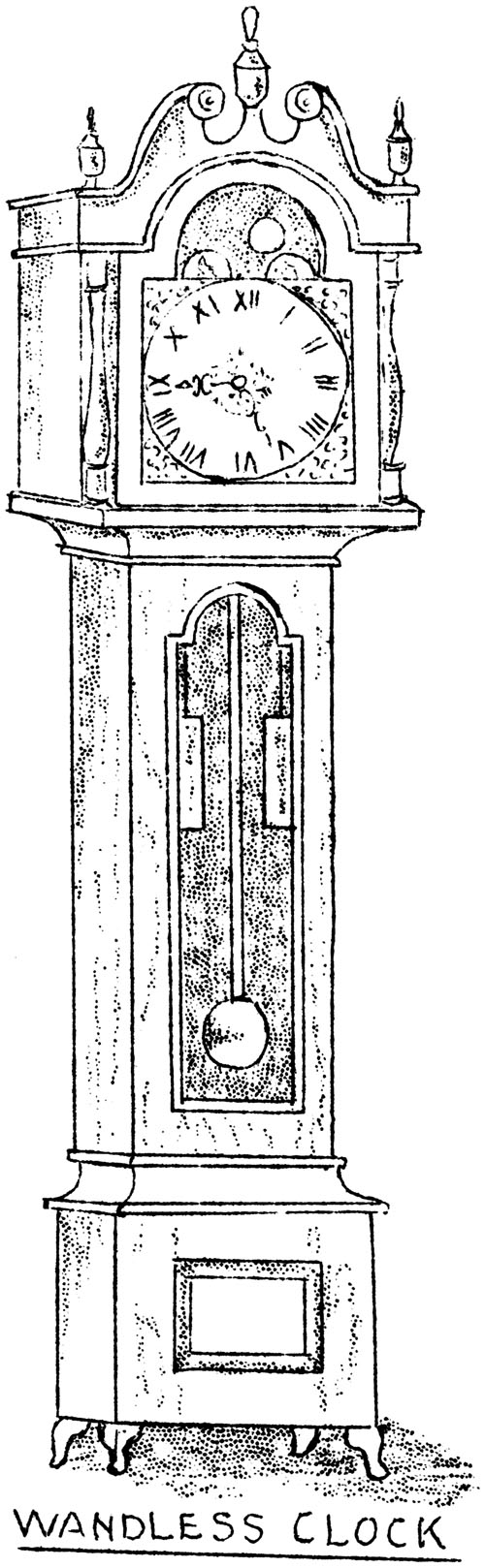

Lefevre Clock An interesting note is the fact that the Dentle block frieze around the lower edge of the hood of the clock was carved by Mrs. LeFevre. To make the wide moldings at the joining of the base and the clock waist and between the waist and the hood, as well as the goose-neck molding at the top, white pine was glued to the back of the 3/4" mahogany so that the flowing curves could be made and the wood would be reinforced. Before he completed the hood of the clock, Mr. LeFevre went to Brettinger's, a clock store in Philadelphia, and made an exhaustive study of all the works in the store. He then selected a type of works and copied the mat, by rubbing the design on paper, so that he would have the proper measurements for his clock hood and that the works would fit when they were installed. To give the proper finish to the case, fifteen coats of varnish were applied and each coat was rubbed with pumice, except the last coat which was rubbed with rotten stone. After completing the case, it stood without any works in it for three or four years. Then, one day when Daniel had the money, he traveled again to Brettinger's in Philadelphia and spent some time listening to the chimes and strikes of various works. Finally he selected one, and he was told that it was exactly the same works which he had selected to make the copy of the mat four years before. The works with the face included came from the Kenzlie Clock Works in Germany, and the Westminster chimes do have a beautiful tone, when they chime every quarter hour and four times for the full hour. There are three weights, one which weighs 48 pounds for the chimes, one which weighs 25 pounds for the strike, and one which weighs 24 pounds for the time. The cables of braided brass wire have been replaced once. In order to wind the clock, a crank is used, and there are three openings in the face, one for each weight. The pendulum is one meter (39.37") long and each swing causes the second hand on the face to move. The moon face shows the phases of the moon during the month. Mr. LeFevre made grooves along the sides of the bottom of the hood, so that it can be slid forward when he wants to tune the chimes. The clock has been in use constantly ever since it was constructed over forty years ago, and for years no adjustment has been necessary. Mr. LeFevre told a friend, a while back, that the clock keeps such accurate time that it regulates the price of potatoes in Ireland! In realizing his desire, Daniel LeFevre has indeed constructed a thing of beauty which is a joy forever. A few years ago Mr. LeFevre made a grandmother clock which is now owned by a niece, Mrs. Richard Benedick of Lancaster, Pa. The desire to own a grandfather clock, coupled with the incentive to try to make a fine piece of furniture, had always been a dream of Franklin W. Wandless. Then one evening in November, 1950, he came home with the works from a mission clock which Clifford Hood, a neighbor on Warren Avenue, had given him, and he decided that the time had arrived for him to realize his wish, and he would build a grandfather clock. The selection of the design was the first problem, and, after studying the pictures and sketches of many grandfather clocks, Mr. Wandless finally settled on a colonial design which he modified to suit his taste. An example of this is the glass panel in the door, put there so that the swing of the pendulum could be seen. The size of the clock is 6'8" from the top of the finial to the floor. The base is 19" wide x 13" deep x 18 1/2" high. The waist is 37 1/2" high x 12" wide x 9" deep. The hood is 18 3/4" wide x 12 1/2" deep x 20 1/4" high. The lumber was purchased from a man in Malvern for $15.00. It consisted of well seasoned, rough walnut boards 3/4 inch in thickness, which had to be hand planed before working it. The moldings were made of the walnut with cutters used in a small drill press. The large cove molding at the joining of the base and the waist and between the waist and the hood was made on a circular saw. The finials and decorative spindle columns on the hood were hand turned on a small lathe. The entire case was glued and screwed together.

Wandless Clock The finishing of the case called for a lot of patience. First it was thoroughly sanded, then it was given two coats of clear shellac, each coat being sanded; next it was given six coats of Butcher's paste wax and it was rubbed down with a combination of rotten stone and water between each application of the wax. Finally it was polished with lamb's wool. To make the face, Mr. Wandless decided to use metal. He first tried steel with machined discs but abandoned that design and used aluminum which he hand painted with an ivory background, using gold leaf to make the decorative scrolls which are outlined with black paint. At the top of the face the Eastern and Western hemispheres are shown in color. It has Roman numerals to designate the hours. The delicate hands, which were hand sawed out of sheet brass in an intricate design copied from a standard colonial pattern, are beautiful. A moon disc moves across the top arc above the dial of the clock against a dark blue sky studded with stars. After the clock had been completed and was in operation for some time, it was discovered that the moon rose too frequently, which indicated an error in the timing of the moon phases. Since the family enjoyed seeing the moon come up it was decided not to correct the faulty operation, consequently this clock has four full moons appearing every twenty-eight days. At the end of approximately four months work in the evenings and on Saturdays and Sundays, the clock case, in its three separate parts, was brought from the cellar to the first floor to be assembled and to have the works inserted and adjusted. The works, dated 1908, are made of brass and the clock is wound by pulling the square, cast-iron weights by chain to the top of the clock. The weights weigh 65 pounds each, and one weight governs the time while the other one governs the strike. The strike is a spiral steel wire. It sounds on the half hour and the proper number of strokes to designate the hour. It is a seven-day clock. The pendulum swings sixty strokes to the minute. Unlike the "Grandfather's Clock" of the song which "Ticktocked" for ninety years without stopping, this clock is very temperamental. If it is not stood just so, it will stop or lose time or gain time. It has developed several tricks which it will play if it is not treated with proper respect. One time the hands caught so that it kept time and struck properly but the hour hand stayed at seven o'clock. It had a period when it would gain during the first half hour, then the hands would drag enough on the second half hour to make the time right by the hour strike. If it is not wound at the proper time the strike will be off. It has become a very important part of the household because after it was assembled the problem was presented as to where to place the clock. To make a suitable place for it, the door of the living room leading into the hall was removed and it found its niche where it now stands proudly telling time for all who would enquire.

Wall of Troy moulding, Dentle moulding, Clock hands, Corinthian Column |