|

Home : Quarterly Archives : Volume 43 |

||||||||||||||||||||||||||||||||||||||

Tredyffrin Easttown Historical Society |

||||||||||||||||||||||||||||||||||||||

|

Source: Spring 2006 Volume 43 Number 2, Pages 62–70 REAL COLONIAL WOMEN DON'T WEAVE CLOTH

In 1982, two books, Real Men Don't Eat Quiche quickly followed by Real Women Don't Pump Gas, give advice about how to be masculine in a modern society that no longer allows a man to be called out for a duel and, for women, how to be appropriately feminine as expectations of them were rapidly changing. Real colonial women in this area, anyhow, didn't weave cloth and this is their story. I'm going to talk about the who, what, why, when, and where of spinning in colonial times but not too much about the how, or we'd be here for hours. I'll focus on the Delaware Valley and, as much as I can, on Tredyffrin Township, Chester County. I've chosen the time period 1700 to 1780. I'll talk about how demographics, politics, gender norms, and economics shaped textile manufacturing and at the end we'll explore a few of the myths. I start around 1700 because not too much was happening in Tredyffrin Township before 1700. William Penn got the Philadelphia area started in the 1680s. People got to this area a little later. I stop at 1780, not because of the Revolutionary War, but because of industrialization. Inventions like the flying shuttle, spinning jennies, spinning mules, and water frame were starting to come into use about this time and dramatically changed the whole picture. If it were the 1730s and I took my clipboard and went over to the Blue Ball Tavern on the Lancaster Pike in Tredydffrin Township and asked passers-by, “From which country did you or your ancestors emigrate and why did you come?” the number one answer would be England, then Wales, then the Scotch-Irish or Irish from the British Isles. Then a smattering of Germans, Scandinavians, and Dutch. Most of these were people from the middle ranks and were prosperous artisans, yeomen—land-owning farmers—or lower gentry. Religious tolerance was one reason people came, but the main reason was for economic opportunity. Lots of things were changing in England with a shortage of land and increasing populations. The cities were not necessarily very nice places to live. If you were the fourth son of some gentry, you didn't have good prospects. A lot of the people from England were Anglican—Church of England—so they weren't being persecuted because of their religion. This area quickly became quite prosperous because of the fertile land. The British subjects brought their culture and traditions with them and were settling in a British Colony.

What was going on in England at the time is a good indicator of what was happening here. The colonists who came from East Anglia to America left a sophisticated manufacturing economy where men, not women, did the weaving. This wasn't always the case. Through the early Middle Ages, women did all phases of textile manufacture. In fact, the word “wife” seems to be etymologically related to the word “weave.” But with the commercial expansion of the late 14th and early 15th centuries, weaving became solely a male occupation. It had a lot to do with the rising strength of guilds. The guilds had strict requirements about who could join and who could weave. Guild regulations and municipal statutes forbade weavers from employing females. Also, the conditions under which an apprentice lived and worked weren't suitable for women, and an apprenticeship was required. Craft guilds guarded the long-standing craft traditions and carefully governed the entry of workers into their organizations in an effort to sustain reasonable wages and a good standard of work. The women had always participated in spinning and continued to do all the spinning. The formal exclusion of females from the cloth-making and finishing sectors of textile manufacture was an important stricture, with the only exception being that the widow of a weaver could officially take over her husband's work and tools as long as she did not remarry. Laws restricting women from weaving persisted until about 1825. There was quite an organized division of labor. Subdividing the work increased productivity by reducing “every man's business to one simple operation.” So, if you purchased a piece of broadcloth 12 yards x 1¾ yards, 15 people probably had a hand in making it, with 5 or 6 people spinning and carding to produce enough to supply the weaver. Spinning was often the limiting factor. A weaver might have spent one day a week just trying to find enough yarn to weave.

Spinning is easier to work in around other tasks. It requires less space and equipment than weaving. A wheel would fit in the corner of the kitchen. A spinner could stop and start as she tended to other household tasks. A loom was typically kept in a separate building. They were called barn looms and required a floor space about the size of today's queen-sized bed. In addition, weaving was dirtier work because of all the manipulation of the fibers and the sizing which was typically a gluey starch added to the fiber for strength. One of the ways textile manufacturers attempted to solve the problem of a shortage of yarn was to have inmates of poorhouses, orphanages, and prisons engage in spinning. It was also a way for rural women, especially widows and “spinsters” to earn needed income. “Spinster” served as a legal title for unmarried women until well into the 20th century. In older records, if the occupation was listed on a marriage certificate as spinster, it signified that the woman was unmarried when she came into the marriage, not that she spun for a living. Now, it's a derogatory term akin to “old maid.” Other words and phrases originate from spinning. For example, “distaff” refers to the female lineage and “dyed in the wool” stems from wool that was dyed before it was cut, spun, and woven, and now means “at the very beginning” or “a deep characteristic.” There is also “spin a yarn.”

In England, wool was the king of fibers. It was a major source of income in the early 18th century. Finished wool textiles were the country's major export. At one point, a law required that people be buried in woolen clothing. Many people were moving from occupations in agriculture to the textile industry. Spinning and weaving are just the tip of the iceberg with regard to textile production. To get to the wool broadcloth from which a suit was made, there were quite a few steps to go through. You had to raise sheep, wash them, and shear them. You had to scour or clean the wool with things like urine. You had to card it—comb it through wire teeth to straighten the fibers and get some of the dirt out—after you'd greased it with goose fat. Then it was spun, woven and possibly dyed. I've purchased a fleece and have processed it through to a woven article. Even with modern detergents, the hot water heater, the spin cycle on my washing machine, and a fancy drum carder, it took many hours to clean up the wool just to the point where I could get it to my wheel. Spinning takes hours and hours and then finally comes the weaving.

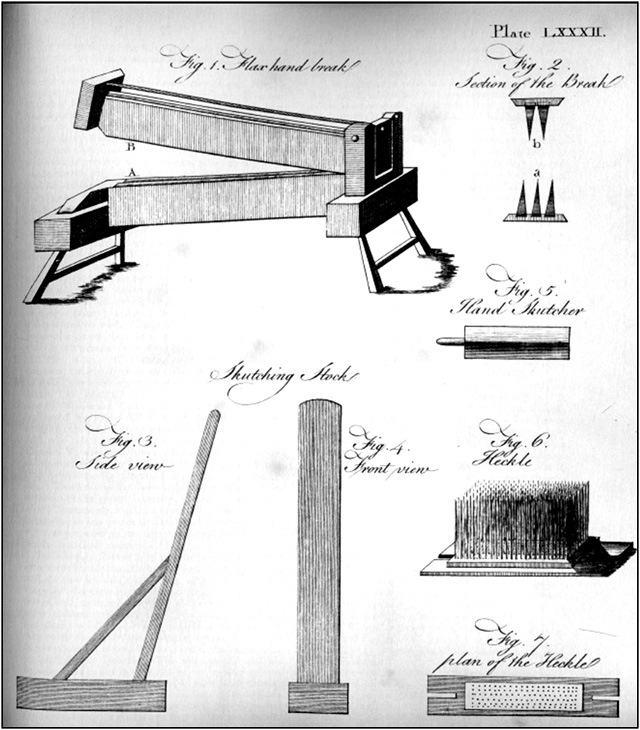

Flax fibers grow around the main stalk If that makes you feel a bit weary, let's talk about linen. When flax, a bast—or plant—fiber that grows about a yard high, is processed and woven it becomes linen. Linen was not produced in England since it was very protective of its woolen industry. In an attempt to help Ireland become more prosperous, the British government decided to promote linen production there and provided tax incentives, tariffs, and encouraged artisans from continental Europe with linen skills to immigrate to Ireland. There was plenty of cheap labor in Ireland for the onerous chore of flax preparation and spinning. Ireland became the capital of fine linen manufacturing. To grow flax you plow the land twice, plant seeds close together so it grows tall with little branching, hand weed it, and, when ripe, pull it—cutting it will discolor it and keep the fiber from being as long. It is back-breaking work. Then you dry it, remove the seeds, and rett it—submerge it in a pond for a couple of weeks so it rots and the fibers separate. Then you dry it again, use a flax break to pound it to loosen the bark and connective tissue, and then scutch it—use a wooden sword-like tool to strike against the fiber to remove the bark and connective tissue. Next you hackle [there are many ways this was spelled at that time; I have used the modern spelling] it by repeatedly drawing it through a tool with many long, sharp metal teeth that rids the flax of short fibers—the tow—and bark. Then it is spun. It's harder to spin flax than wool, as it's long and wiry. In summary, in England and the rest of Britain weaving was an official occupation for men and part of a well-organized industry. Spinning was done by women and children and the indigent. An ordinary citizen could easily buy cloth. No single person participated in the entire process from start to finish.

Flax tools. Upper left: hand break, bottom center: skutching stock, bottom right: heckle.

I became interested in spinning and weaving after my cousin, in doing some genealogical research, found out that we were related to Colonel William DeWees, who managed the forge at Valley Forge for William Potts at the time of the Revolution. He married William Potts' sister, Sarah. He was a leader of the local militia and our uncle five times removed. The DeWees family came to New York from Holland and then bought land in Germantown in 1690. They started the first paper mill in the colonies there. One of the brothers who immigrated, Lewis, was listed as being a weaver “pursuing his avocation in Philadelphia for several years before buying land in Delaware where he raised a family of children.”

That was typical of weavers. They often immigrated and worked as weavers until they had the means to buy land. It was much easier to earn money here by farming, rather than by weaving. Land was available at a good price and was the key to status, voting, and wealth. Philadelphia was a ready market for agricultural products and a close supply center. After turning to agriculture, a weaver might continue to weave in the off-season or have an apprentice or employee work on the loom. Their primary occupation was farming; weaving was secondary. It's not uncommon to see a person's occupation change, typically away from a craft that they might have arrived with, to farming. Another example of this is Squire Boone, Daniel Boone's father. He was a Quaker who came from Devonshire in the 1730s. He immigrated as a weaver, acquired land, then his major source of income was farming. He was also a blacksmith. Many Germans settled northwest of Chester County and there were many excellent weavers among them. At that time, in Germany, you could not own land if you were not Lutheran so non-Lutherans often became craftsmen. The lure of religious tolerance and economic opportunity brought them to Pennsylvania where they could own land and become successful farmers as well as practice their craft.

Tradition held, here in the colonies. Men did the weaving and women did the spinning, with one big difference. There was no organized industry here. Typically, there was a single weaver, with maybe an apprentice or son, working in a small workshop or shed by his house. People in the area would spin their yarn and take it to him to have it woven according to their needs. It was called “bespoke” weaving. Likewise with shoemakers; you brought them your own leather. Unlike urban weavers who might specialize, rural weavers made a variety of linen and woolen goods. Some of the household goods they wove were sheets, towels, blankets, grain bags, and wagon covers. In the Tredyffrin tax records of 1798, four men were listed as weavers.

What was the major agricultural product exported from this area? Wheat. Wagonloads of wheat would go to port in Philadelphia for export to England and other places. The second biggest export commodity was bread, in the form of hardtack, which is twice-baked bread or biscuits, like rye-crisp. This was a big grain-producing region. Rye and oats were used for hardtack as well. The third biggest export was flaxseed. The main reason for growing flax in the colonies was for the seed. This was used industrially for linseed oil—a yellowish oil used as a drying oil in paints and varnishes—with the resulting mash used for animal feed because it had a high protein content. I'm guessing that this was the third largest export commodity based on its monetary value rather than its volume. The Irish were the specialists in fine linen. They knew that flax was of higher quality if it was pulled before it seeded which created the problem of having no flax seeds to plant the following year. So they were buying American seeds. Our flax was of a lower quality but still useable. To the frugal American colonists, the flax fiber was a useful by-product of the seed production.

The main reason for raising sheep here in the colonies was for fertilizer. I didn't believe it myself at first, but I've read it in too many different places for it not to be true. There were no artificial fertilizers then. Sheep dung was considered necessary for a good corn crop. Sheep also provided mutton for meat, skins, and tallow—the hard fat obtained from the carcasses used in food, or to make candles, leather dressing, and lubricants. They also provided lanolin—a fatty substance obtained from the wool and used in cosmetics, soap, and ointments—and certainly the wool. It was too hot to not sheer sheep around here and they were sheared in the spring so they wouldn't become ill or turn into insect factories. The early American sheep were common mongrel breeds, not the Spanish merino—an African/Spanish hybrid—with the long, lustrous coat favored by the British. Our wool was short, thin, and coarse in comparison; too poor to comb for the higher quality fabric. The resulting wool, in addition to being carded for spinning, was used for stuffing, padding, felting, pillows, saddles, etc. Carding and spinning were done in the winter months or in spare time.

Hemp, another bast fiber like flax, was used when more durability was required such as for rope and Conestoga wagon covers, and as well as for a linen-like fabric. It was a taller plant and therefore had a longer fiber. In color, it was more reddish yellow, but it was difficult to distinguish from linen in its final form. It doesn't appear to have been grown much in Chester County but was common in Lancaster County. Hemp was one of the products with special incentives for export because the British Navy required it for rope and lines for their ships. Les Stark, a restaurant cook and part time historian, studied hemp production and read through Lancaster County wills from1729-1845. His book, Hempstone Heritage I, In Accordance with Their Wills, All the Heckled Hemps She Can Spin [Morgantown, PA: Masthof Press, 2005], is the result of this research. Here are snippets from the wills that deal with fiber: Philip Brenner: 1783-1788 All my yarn, flax, and hemp in my house or at the weavers at the time of my decease shall go to my daughters Ann Maria, Sussanna and to my beloved wife Ann Elizabeth. My wife shall also have 15 pounds of hackled hemp and 3 pounds of wool yearly and every year she remains a widow. It's typical of all these wills that a certain amount of flax, hemp and wool is given to the wife. Note the reference to work at the weavers. Martin Barr/Bare: 1757-1758 wife Elizabeth Barr with 12 pounds of heckled flax, 12 pounds of hackled hemp, and 4 pounds of wool yearly, and every year during her life, but if the flax miss, then he shall deliver all in hemp. I noticed a failed flax crop referred to in several wills; I'm guessing that while they were retting it—the rotting process—things might sometimes go awry and a substitution of hemp was supplied. Rudolph Bollinger: 1770-1772 My beloved wife Catharine Bollinger shall have 4 gallons of whiskey, 10 pounds of wool, 10 pounds of heckled hemp, 10 pounds of heckled flax, and as much tow (?) of each sort yearly. He obviously loved his wife. Tow was the shorter fiber retained in the hackles during the fiber preparation. There were some attempts to grow silk in the colonies but most were unsuccessful. Both silk and cotton were imported and silk more so than cotton. Cotton was never a big player in the colonial homespun industries. Records show that it was grown as an ornamental. Indian cottons—they had cheap enough labor to pick the fiber off the seeds—were banned in Britain in attempts to protect the British textile industry but small amounts of cotton fabric made it to America. The situation with cotton changed dramatically in 1793 when Eli Whitney's mistress invented the cotton gin. In Chester County, the women didn't weave but they did all the spinning. Wives made most of their own and their children's clothing and the household textiles. Sometimes a servant or hired help did the spinning. The daughters were occasionally apprenticed to learn spinning. Spinning did not have the formal and therefore the taxable occupational status of the male-dominated crafts so there are fewer records of it. It was considered an extension of household duties. Tax records, wills, etc. reported the occupations of men. When you had enough of any of these fibers spun, you would take it to the weaver and tell him what you wanted. He gave back a bolt of cloth, unfinished. It still needed to be dyed and finished, which is an elaborate process done by another professional, the fuller. The fuller was the drycleaner of their day. In the fulling mills, the cloth was pounded to make it more dense, brushed to raise a nap, and then carefully trimmed. The fuller did the dying since it required special materials and skills.

Above: The author spinning on her great wheel at home. Photographed by Mike Bertram, July 2005.

Below (refers to image above, img_v43n2p066b.jpg): The author spinning flax on her Saxony wheel with a flax strick to her left. Photographed by Joyce A. Post, March 19, 2006. Kathy's costume is all-linen and is worn at Valley Forge and other re-enactments.

Barn loom from the 18th century at the Daniel Boone Homestead. Photographed by the author, May 2006. Most homes had a spinning wheel or two. Wheels typically were not made by fathers or husbands, but were made by skilled craftsmen, often furniture makers listed in census records as joiners, cabinet makers, or even wheelwrights. At that time, married women owned no property. Even if a woman came to the marriage with her own wheel, it became her husband's property. Upon a husband's death, if there was no will, the widow had to buy her own wheel from her husband's estate. A good spinner could spin two skeins of linen yarn in a day. A spinner was paid 8 cents a day, the equivalent value of a loaf or two of bread. Looms could be made by a somewhat competent carpenter. They are basically sticks and string. You could buy a reed—the comb-like tool used to space the warp threads and beat in the weft—and possibly a few metal parts such as gears for tensioning the warp. If you want to see an old traditional barn loom, there is one in the visitor's center at the Daniel Boone Homestead in Berks County that is beautifully warped, and another one at Hopewell Furnace that will be operational soon. Many barn looms still exist and can be purchased for about $400 providing you have plenty of space. As early as 1630, textiles were available at general stores in the American colonies. By 1712, Chester County millers, who typically served as the general stores/trading posts in early times, sold European fabrics, which were symbols of status. It was important to keep in style with those back home in England. Dolls were shipped clothed in the latest fashions and with the latest hair styles. Women were embarrassed if caught in their homespun apron by a visitor. According to the August 8-15, 1728 American Weekly Mercury—Benjamin Franklin's Pennsylvania Gazette didn't start until a few years later—merchants in Philadelphia advertised the following for sale: Oznabrigs, garlicks, calicoes, duroys, shalloons, shrouds, duffles, stripe blanketing, blankets, hats and sundry other sorts of linens and woolens lately imported from London [which could] be paid for next spring in country produce. Barter was an acceptable means of payment but cash was common for such transactions. A bewildering array of cheap as well as expensive textiles and ready-made clothing arrived on a regular basis. Cloth and sewing materials made up ¾ of all imports in the port of Philadelphia. The English consumers complained that cloth was cheaper in Philadelphia than in Manchester, one of the major centers of textile production. In Philadelphia, there were many tailors, but few weavers. Readily available did not mean cheap. Probate records of household inventories from the 18th century show that often the textiles listed in a household estate were worth more than the wrought silver—also an important symbol of status. There was quite a market for second-hand clothing. Theft of clothing was common, as evidenced by notices in the newspapers and by locks on wardrobes. Examples of what has survived are the fancy items, those imported from Ireland, France or the Orient. There's very little of the plain sewing left. Everyday items—what would have been made in this area—were used until they wore out. Worn textiles were sold as rags for paper or shoddy—a cheap, recycled woolen fabric. In summary, a weaver could do much better as a farmer, selling his wheat and using the profits to buy most necessities. A vibrant economy made it possible for most people to buy fabric produced outside the home, whether locally or imported. Imported fabrics were a status symbol. In monetary terms, textiles were by far the largest commodity imported into the colonies. An increase in materialism among colonial Americans assured that they were an integral part of the burgeoning trans-Atlantic consumer culture. Up until the early 1700s, sumptuary laws attempted to “restrict the sumptuousness of dress in order to curb extravagance, protect fortunes, and make clear the necessary and appropriate distinctions between levels of society.” For several centuries in Europe, these laws were common although difficult to enforce. Money was deemed better spent on more important things. Another concern was that letting anyone wear what they wanted to wear must inexorably lead to moral decline. If you couldn't tell a milkmaid from a countess at a glance, the very fabric of society might unravel. By the middle of the 18th century, even the lowest scullery maid could wear lace if she could afford it.

England considered the colonies a source of raw materials—wood, hemp, wheat, fish, pitch—and a ready market for finished goods. Pitch—a resin obtained from pine trees used for waterproofing and caulking—was another product important to the British fleet. Laws prohibiting manufacturing and limiting imports and exports were established starting in the mid 1600s. These Navigation Acts confined colonial trade to England. Imports were to come only through a British port, on a British ship, with at least a 2/3rds British crew in order to prevent the colonies from trading with other countries. These laws encouraged smuggling to avoid tariffs and to circumvent trade restrictions. One piece of legislature stated that “Americans had no right to manufacture even a nail or a horseshoe,” which prompted a colonial wag to remark that soon they would be sending their horses to England to be shod. In 1698, some Americans manufactured and exported wool to France in exchange for silk textiles. The hint of growth of a woolen industry in the colonies was regarded with jealous eyes since wool was the economic backbone of England. The Crown, aided by the governors of the colonies, sought to maintain England's monopoly by regulating wool production in America through the Wool Act of 1699 and subsequent further restrictions. A 1705 edict of Lord Canbury, governor of New York, written in a letter to the British Board of Trade, stated: No wool, woolfells, shortlings, morlings, wool flocks, worsted, Bay or Woolen yarn, cloth serge, Bays, Kerseys, Says, Frizes, Druggests, Cloath Serges, Shallons or any other Drapery, stuffs or woolen manufactures whatsoever, made or mixed with wool or wool flocks, being the product or manufacture of any English plantation in American shall be laden on any ship or vessel. Laws specifically stated that wool products could not legally be transported across any body of water including the smallest creek and trade between colonies was restricted. Improved breeds of sheep or any wool producing equipment was not to be imported. If someone was caught and found guilty by a jury of his peers—an unlikely event—the result was forfeiture and a 500 pound fine. Very seldom was there any real attempt at enforcement of these laws although their existence did limit the formation of an organized textile manufacture.

Cloth manufacturing acquired political meaning when the 1760s Stamp Act resulted in a self-imposed boycott of British goods by the colonists. Here is an example of an admonition from a newspaper during the years of the Stamp Act: In Philadelphia, any person found so dead to all warm emotions of the heart, when liberty was at stake, as to import any of the hated merchandise was threatened not only with loss of custom but also with most abject contempt. And perhaps a bit of tar and feathers, courtesy of the Sons of Liberty. Cloth production was stepped up, but there was a shortage of raw materials, skill, and labor. By the middle of the 18th century, Germantown had become a center of stocking manufacture. Men used a stocking frame, or loom, to mechanically knit stockings. By 1777, one hundred Germantown stocking weavers were out of employment due to a lack of raw materials. From Massachusetts to the Carolinas, the women of the colonies banded together in patriotic societies called the Daughters of Liberty, agreeing to wear only garments of homespun manufacture and to drink no tea. Spinning frolics, social gatherings where the women spun and held spinning competitions, were common in many towns. A Newport, Rhode Island, newspaper article reported how a 71-year-old woman who had “never spun a thread in her life before” became a good spinner to support the war effort. Page 69 When the war started, the shortage of textiles became a serious problem. Keeping Washington's troops supplied with blankets and clothing was problematic throughout the war and limited the army's efforts. The people at home didn't have much either but sent what they could spare to support the war effort. General Howe knew that “linen and woolen goods were much wanted by the Rebels.” Hence, when his army prepared to evacuate Boston he ordered all such goods to be carried away with them. Smuggling continued to be an important way for European goods and supplies to reach the colonies during the war.

Why have we been misled about colonial textile manufacture? The spinning wheel had became the icon of the industrious colonial housewife; the matron of the self-sufficient household, spinning in every spare moment, once or twice a year going to the general store for some sugar and a trinket for the kids. It is partly due to a New England-centered interpretation of the American history of textiles. The early diaries that are quoted so often are from New England where the pattern of settlement and livelihood was different from this area. Agriculture wasn't the big money maker there that it was here and there was greater economic hardship in the earlier northern colonies. Men were often away from home cutting timber inland or out on the seas. Women did spin and weave more up there, but they would still weave at home and often sell their homespun items to buy English-made garments or ribbon for their hats. There is evidence that they bartered with neighbors with homespun articles and shared weaving equipment. Another reason is that there is the assumption that the majority of immigrants to North America from Europe were poor and down-trodden. The truth is that most immigrants to this area arrived with money and were used to a good life. Finally, there is the ubiquitous romanticization of the past. A colonial revival period occurred at the turn of the 20th century and the resulting publications from that time are the sources for much of the misinformation. Here is an example of a typical myth: A woman would jump on horseback in the early morning, and with a baby in one arm and a flax wheel tied behind, would ride several miles to a neighbor's to spend the day spinning in cheerful companionship. I doubt the wheel would have survived the ride.

Prominent people were often the subject of these myths. One source states that “During the Stamp Act boycotts of the 1760s, Deborah Franklin, wife of Benjamin Franklin, made all of the cloth for her family as she had done when they first married.” Here is a section from one of Ben's letters from London: As the Stamp Act is at length repealed I am willing you should have a new gown, which you may suppose I did not send sooner as I knew you would not like to be finer than you neighbor's unless is a gown of your own spinning. Had the trade between the two countries totally ceased, it was a comfort to me to recollect that I had once been clothed from head to foot in woolen and linen of my wife's manufacture, that I never was prouder of any dress in my life, and that she and her daughter might do it again if it was necessary. I told the Parliament that it was my opinion, before the old clothes of the Americans were worn out they might have new ones of their own making. And indeed if they had all as many clothes as your old man has, that would not be very unlikely, for I think you and George reckoned when I was last at home [I had] at least twenty pairs of old breeches. Joking apart, I have sent you a fine piece of Pompadour satin, fourteen yards, cost eleven shilling a yard; a silk negligee and petticoat of brocaded lutestring for my dear Sally, with two dozen gloves, four bottles of lavender water. Noting the “joking apart” comment and knowing something of Ben's personality, I am sure he was being facetious about Deborah's spinning and weaving. Deborah ran the stationary store as well as the household which included several printing apprentices and servants. The Franklins were certainly prosperous enough to purchase the textiles they needed from the abundant supply of merchants in Philadelphia. Cokie Roberts in her book, Founding Mothers, relates another story about Franklin. When his sister was getting married, she was expecting the gift of a tea table, but he sent a different gift with the note: “Knowing you're such a practical woman, here's a spinning wheel instead.” Another myth: “During the Revolution, it is said that in a day and a night a mother and her daughters in Townsend, Massachusetts sheared a black and a white sheep, carded from the fleece a gray wool, spun, wove, cut, and made a suit of clothes for a boy to wear off to fight for liberty.” A blanket requires two fleeces and over two weeks of work for one person: fiber preparation takes seven 8-hour days, after that there are 5½ days of spinning, and four days of weaving. There would have been no time to wash the fleece in that time frame so it would have been a very smelly suit. Another story from Connecticut claims the process of suiting up a lad for the war was done in a week. The story goes on: “. . . it was winter, so the generous sheep were protected by wrappings of braided straw” and this part could be true.

Another prominent person myth: It is said Martha Washington carefully dyed all worn silk gowns and silk scraps to a desired shade, raveled them with care, wound them on bobbins, and had them woven into chair and cushion covers. Sometimes this process was reversed. In this quote, I keep the original words and feel the reader can easily understood what is reported. Obviously the person who reported this didn't know much about processing silk. Because of the length and fineness of silk fibers, they don't recycle as easily as wool, and silk is one of the hardest natural fibers to dye. Weaving did take place at Mount Vernon and other southern plantations where slaves spun and wove cloth for slaves clothing and household linens. A weaving friend of mine who has volunteered at Mount Vernon imagines the practice of weaving in bits of silk thread into a linen or woolen fabric was the seed for this myth. The silk thread could be woven into the homespun products for stripes and accents. It enlivened the fabric as the threads of silk caught the light.

When spinning on a great or walking wheel, the spinner stands and moves several small, rocking steps back and forth with each length of yarn spun and wound onto the spindle. In an English source it is said that spinners who worked for the textile industry in Yorkshire and Lancastershire walked the equivalent of 30 miles a week in spinning wool. An American source states: “it was a good day's work for a quick spinner to spin six skeins of yarn a day. It was estimated that to do that with her quick backward and forward steps, she walked over 20 miles, or 100 miles a week.” Was spinning really such a long-distance activity? I did some calculations based upon some reliable estimates of how much a good spinner could spin in a day assuming someone else did the time-consuming task of carding the wool. Being generous, I estimated that a spinner, if really motivated and undistracted, would walk the equivalent of 20 miles in a week. The Americans weren't more athletic, they were poorer at math. Both of the following statements were found in books about colonial women after the war. Which is true? A. “Even at the end of the Revolution, women continued to spurn English goods,” or B. “Feelings of patriotism notwithstanding, American women were eager to give up the wheel for store-bought goods and factory cloth from England.” The answer is B. Even those living at the time had misconceptions about colonial textiles. Here's a quote from the diary of a visiting Englishman, who was dining at a private home in America: The old-time board-cloth [tablecloth] was in no way inferior in quality or whiteness to our present table linens; for we know how proud colonial wives and daughters were of the linen of their own spinning, weaving and bleaching. No American-made textiles matched the quality of European linens in fineness and the number of threads per inch. The best from America was probably 40 threads per inch. In Ireland, it was 90 threads per inch. My guess is that the wonderful tablecloth that the ladies set out to impress their guest was probably purchased from Ireland. And one final outlandish myth: “The Virginia assembly estimated that five children under 13 years of age could by their work readily spin and weave enough to clothe 30 persons.” Why let the truth ruin a delightful story? By the 1780, we are to the point in time where flying shuttles, power looms, cotton gins, spinning jennies, spinning mules, water frames, and other mechanizations dramatically changed textile production. All that might be a topic for another day. Kathy King entered the intriguing world of spinning and weaving when she retired from chemical engineering several years ago. She now has 4 looms and 3 spinning wheels and many wonderful new friends. Presented at the March 19, 2006 meeting of the Tredyffrin Easttown Historical Society. Transcribed by Bonnie Haughey. |

||||||||||||||||||||||||||||||||||||||